A kit aircraft is defined by the Federal Aviation Adminstration (FAA) as “experimental,” a category that was originally created so that aircraft manufacturers could perform test flights on their prototype aircraft. The experimental category has evolved over the years and now includes a sub-category for amateur-built aircraft (FAR 21.191(g)): “Operating an aircraft the major portion of which has been fabricated and assembled by persons who undertook the construction project solely for their own education and recreation.”

In other words, the kit buyer is the builder or manufacturer of his or her aircraft. The key is “major portion,” meaning that you, the builder, must perform 51% or more of the actual aircraft fabrication and assembly (the FAA has determined that Zenith Aircraft’s kits meet the “51% rule”). Other key key words are “education and recreation,” meaning that you don’t qualify if you build your aircraft for commercial purposes.

Once a kit aircraft has been completed and registered, the FAA inspects it before it issues an airworthiness certificate (this is a routine inspection of the aircraft, and not an approval process). Once flying, the main operating restriction is that it can’t be used for compensation or hire. The builder can also get a “repairman’s certificate” that allows him or her to perform all the maintenance on that particular aircraft.

For additional information and details, contact the FAA or EAA. Of course, if you’re not in the United States, consult the appropriate civil aviation authority rules.

Note: Kit aircraft are not FAA approved. As experimental aircraft the approval of the designs or assemblies is not required by the FAA or any other entity in the United States. (It’s the main reason we’ve seen so much innovation and many new designs in the industry, but it’s thus important that you research a design before buying a kit and building and flying it).

Rules vary from country to country: In several countries, various Zenair designs have been type-certificated by civil aviation authorities. The Zenith CH 2000 from Zenair Ltd. is a standard type-certificated production aircraft, but it is not available in kit form.

We recommend highly that you join the Experimental Aircraft Association (EAA). This is an organization devoted to sport aviation and homebuilt aircraft, which offers excellent resources and support to builders.

Additional Resources:

Yes, you need a Sport Pilot’s License (in the United States). These designs must be operated like any other aircraft (they are not ultralights in the United States). Zenith Aircraft designs have been developed for sport pilots, meaning that they’re designed primarily for the recreational “weekend” pilot and they don’t require professional piloting or building skills.

The FAA recently passed the new Sport Pilot category for recreational pilots of light aircraft. Click here for

details.

Additional Resources:

All of our aircraft are designed by aeronautical engineer Chris Heintz, who is one of the most experienced and qualified designers of kit aircraft today (with engineering experience from Aerospatiale, de Havilland, and Avions Robin). Heintz has introduced more than 12 new kit aircraft since 1974, and personally oversees design, prototype development and the actual flight test program of each new design. Heintz’ recent ZENITH CH 2000 design received FAA type approval: This production aircraft uses the same construction techniques as the kit aircraft line.

While each Heintz design is unique, it draws extensively on his previous experience, bringing forward tried and proven design and manufacturing experience.

Unlike many kit designs (that are not professionally designed), Zenith Aircraft’s kit designs are the product of extensive and ongoing design and manufacturing development.

Since 1974, there have been over 2,000 kits sold and delivered, and that’s not counting the additional Drawings and Manuals sold separately. We estimate that at least 1000 of these aircraft are now flying, but it’s difficult to quantify since about 50% of our kits are exported around the world.

Our kit completion ratio (the number of kits that actually get completed and flown) is very high when compared to industry averages, a reflection of how quick and easy our kits are to build. Individuals that cannot complete their kits can place them on the used market, but partially completed or used aircraft are typically hard to find.

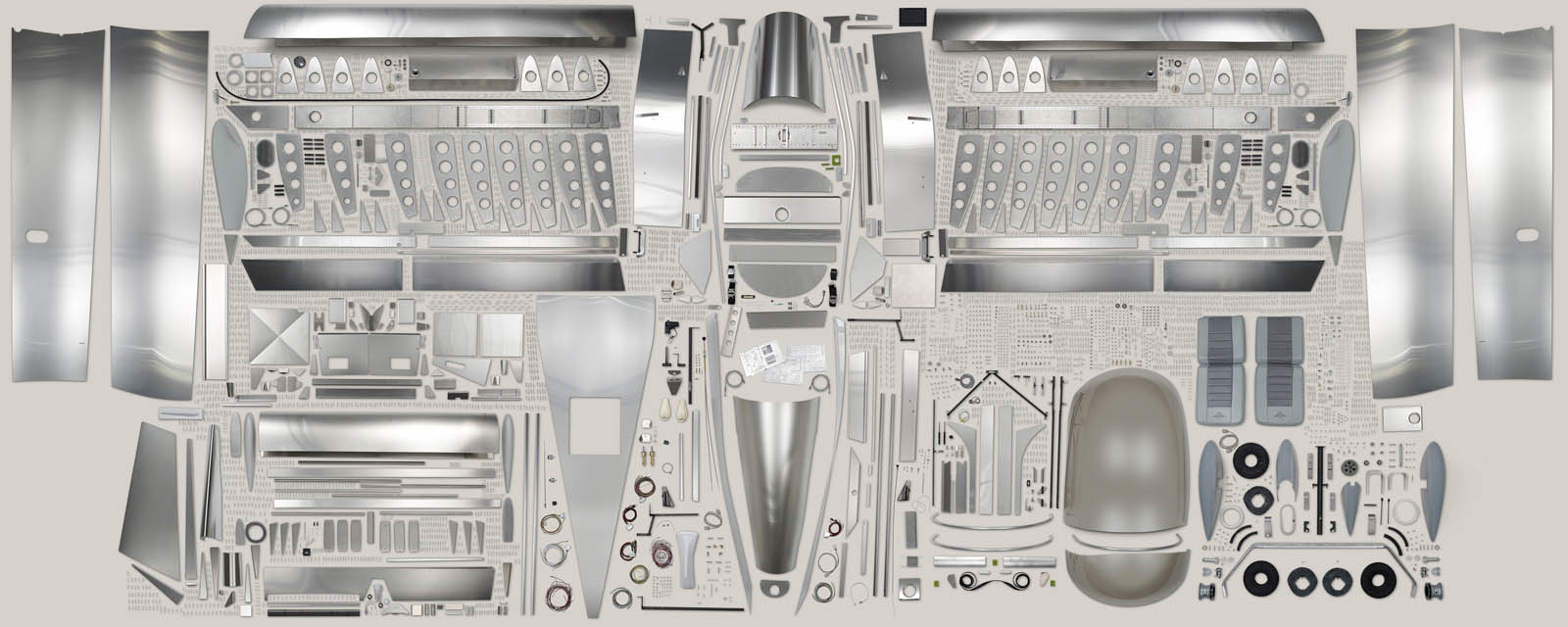

All of our kits are built exclusively from all-metal (aluminum alloy) construction. While each construction type (tube & fabric, composite, etc.) has its relative advantages, aluminum alloy construction continues to be the dominant aircraft construction material. Aluminum alloys’ unique combination of properties make it one of the most versatile engineering and building materials in existence:

- Low weight / high strength relationship;

- Corrosion resistance, especially with newer alloys and modern primers;

- Low cost and widespread availability;

- Proven durability and resistance to sun and moisture;

- Existence of vast amounts of empirical data on its properties (fatigue, stress);

- Easy to work with: requires simple tools and processes, and does not require a temperature-controlled or dust-free environment as with composites. Modern blind rivet fasteners have greatly simplified all-metal kit aircraft construction;

- Environmentally friendly: no health hazards to worry about when working with sheet metal;

- Easy to inspect: construction or materials flaws are easily detected, as are defective parts and damage.

- Simple to repair: rivets and fasteners can be easily removed to replace damaged parts or sections, and individual parts can be replaced without having to replace or rework an entire airframe section.

Chris Heintz has stated that the more experience he gains with aluminum alloy construction, the more he recognizes the medium as the best overall aircraft building material, especially for amateur kit builders.

While it’s true that some all-metal kit aircraft require more skills and tools and higher construction times, Heintz designs have been developed over the past two decades for unparalleled ease of assembly – with very minimal required skills and tools and short assembly times.

For most owners, an aircraft is a long term investment. An all-metal aircraft provides proven durability and lower maintenance costs than fabric-covered or composite aircraft.

Well, yes and no: We certainly don’t use the hardware store Pop rivet brand, but we do use blind rivets extensively (instead of conventional “bucked” rivets). Our kits use Textron’s Avdel Avex blind rivets made from quality alloys, with each imported shipment batch tested by Zenith Aircraft for shear strength before being used. These modern blind fasteners are as simple to set as standard “pop” rivets, and don’t require the expertise and tools required for hammering and bucking conventional rivets, such as pneumatic riveter, air compressor and an assortment of bucking bars. Aside from not having to purchase this expensive equipment and needing to become an expert at riveting, blind rivets represent a number of significant advantages to amateur builders:

Blind Riveting-First, the rivets are pulled only from one side (hence the name “blind” rivet), unlike bucked rivets that need to be driven from one side and bucked on the other side. This means that blind riveting can be done by one person, and the builder does not need to exercise physical contortions to gain access behind the rivet when riveting sections together. Pulling blind rivets is nearly silent compared to the pounding noise of a pneumatic hammer, lending itself well for home projects (without driving the family and neighbors away). Thanks to the innate simplicity of pulling a blind rivet, the process is quick and foolproof. Additionally, the exterior skins are not counter-sunk for flush riveting. While perfectly smooth skins may be aesthetically desirable, they have negligible impact on performance, especially when factoring in the hundreds of building hours it takes to achieve such a finish. Another advantage of blind rivets is their long grip area length, which means that the same rivet size may be used to fasten a wide range of material thicknesses, avoiding the need for a large inventory of different length rivets. While per unit cost is higher for blind rivets, they provide many advantages to homebuilders, and have become very popular with many modern all-metal kit aircraft, providing the required strength, durability, and building ease (they’re now also being used on a number of factory built aircraft).

“There is nothing that looks faster than pop-riveted aluminum. From race cars to airplanes, the blind rivet is the fastener of choice for joining sheet metal.”

Make magazine, volume 05, February 2006, “Holes, Rivets, and Bent Metal”

While all aircraft are designed with certain power and engine weight guidelines, Heintz does not design his aircraft “around” an engine to maximize the customer’s choice of installed powerplant.

At Zenith Aircraft Company, our specialty is airframes and not powerplants. The standard engine on for both the ZODIAC CH 601 series and STOL CH 701 kit aircraft is the Rotax 912, an 80-hp aircraft engine manufactured by Bomardier. We supply our customers with complete firewall-forward kits for the Rotax 912 engine, including the propeller, engine mount, and all other accessories.

Typically, our customers purchase the kit without the engine, and only purchase the powerplant when needed. Unless a builder in mechanically inclined to work on engines, we highly recommend the standard Rotax 912 installation over other custom installations. Most custom engine installations require a lot of work and “troubleshooting” to properly install, and may often not provide the expected performance and reliability. An inexpensive engine may cost you less to purchase initially, but may not provide the proven reliability and performance you expect, and may need to be replaced a lot sooner than expected.

We stock engine mounts and accessories for many other engine types but we do not provide support for such installations.

The official “build” time for our kits is approximately 500 hours. While this figure may seem optimistic, it’s actually quite reflective of actual build times. In putting one of our kits together, you’re simply lining parts up, drilling and riveting – all of the actual parts manufacturing is done for you at the factory.

On numerous occasions we’ve proven just how quick and easy our kits are to build by completing an aircraft (from kit to flying) in just seven days. At the 1993 EAA Sun’n Fun fly-in about 20 volunteers and Zenair staff built a Super ZODIAC CH 601 HDS during the one week convention, and designer Chris Heintz flew the completed aircraft on the seventh day! (The previous year we did the same thing with a STOL CH 701 kit). We haven’t repeated a “Seven Day Wonder” program these past few years – we’ve proven our point are we’re waiting for a competitor to try to meet or beat our feat!

Unlike most other kits on the market, our kits were designed for the kit builder. What this means is that the inherent simplicity of the design makes it easy to build. For example, no real jigs or fixtures are needed to put the aircraft together – just a flat workbench, with all the sections being built up from the flat reference. Also, our kits come with complete drawing (blueprints) of the aircraft, and not just assembly instructions. Actually, about one third of our customers “scratch” build their aircraft from the drawings alone (of course, this takes more time, skills and tools since every part of the kit must first be made).

We’re continuously improving upon the quality of our kits, to make them easier and quicker to put together. With more than 20 years experience manufacturing kits, our kits and manuals undergo continuous quality improvements to make them the most complete, affordable and easy-build on the market today.

How long will it take you to put a kit together? Only you can answer that. We’ve found the single biggest factor affecting build times is large doses of common sense and basic ability to work with blueprints and instructions, and not prior building skills, tools or experience.

Our kit have been painstakingly developed not to require special skills or tools: Our philosophy is to provide the kit builder with all pre-manufactured components that do require any special building skills or tools. For example, the wing spars (which use conventional solid rivets) are completely pre-built at the factory and supplied ready-for-assembly in the kit. That means that you won’t spend a fortune purchasing specialized tooling or spending a lot of time learning new skills.

To learn and experience first-hand the basic kit building procedures, join us for one of our sheet-metal workshops: These workshops are held right at our factory, and give you the opportunity to actually start assembly of your own kit aircraft.

You’ll find it most difficult getting started on the project. While you won’t need special skills or tools, knowing how and where to start is probably the biggest challenge you’ll face with a kit project, and you’ll likely be overwhelmed by the scope of the project at first.

However, once you’ve drilled that first hole and realized that you’re only working on a small section of the aircraft, you’ll find that everything is starting to come together – literally.

The following is an actual quote from a first-time builder who had a hard time getting started:

“Finally got past the jitters and have started construction. What a great project!!!”

To help bypass initial “getting started” difficulty, we recommend that first-time builders attend a factory workshop – where they’ll gain hands-on building experience, and pick up a lot of building tips and hints. If you can’t attend a workshop, expect to have difficulty getting started with the project. However, don’t despair – the above quote is very typical.

The backbone of every kit is the detailed Drawings and Manuals. The Drawings and Manuals are supplied with the complete kit and document the complete blueprints for the aircraft as well as a detailed step-by-step illustrated assembly manual. Actually, you can build the complete aircraft just from the Drawings and Manuals (they’re available separately from the kit and even come with a serial number). The Drawings and Manuals are frequently revised to incorporate any changes or to make the instructions more specific or easier to follow.

Available technical support and builder resources:

- Online builder resources – our exclusive builder Internet web pages contain up-to-date revisions, builder lists with email addresses, an automated builder mail list (forum), building tips, hints and much more.

- Builder Newsletter – the official Newsletter contains updates and revisions, tips and hints, and news from the factory and fellow builders from around the world.

- Technical Support: Every builder has direct access to free lifetime technical support directly from the factory, just a phone call, fax or email message away.

- Join your local Experimental Aircraft Association (EAA) Chapter to meet with other builders and be part of the exciting world of sport aviation. Local builders can provide you with help (and lend you tools, as well!). EAA has a Technical Counselor Program, which provides local technical help and guidance to you with you kit project at no charge. To join EAA, call 1-800-322-2412.

Yes, most builders build all the kit sections in a single-car garage or basement workshop. When building the kit, you’re working on small modular sections, such as a wing, tail section, or rear fuselage. All you really need in your workshop is a large flat workbench. Once all sections are completed, then most builder rent or borrow hangar space to put all the sections together and ready the aircraft for its first flight.

Basically, everything “firewall-back” is included with the complete airframe kit: Every kit part and hardware piece needed to complete the airframe is included as part of the complete kit, including the gear, wheels, brakes, fuel system and controls. We pride ourselves on the completeness of our kits: about the only items not included in the airframe kit is the paint and seat upholstery. Many items included in our standard kits are not supplied or sold as options by competitors.

The complete Rotax 912 powerplant and instrument packages supplied by us includes everything firewall-forward to complete the aircraft and have it ready for flight, including propeller, engine mount and basic flight and engine instruments.

Oh yes, batteries are not included.

Our customer base is very diverse (we have over 2,000 customers in more than 45 different countries). While the vast majority of our customers are pilots, very few of them are mechanics or even very mechanically inclined.

If you’ve read this far, chances are that you’re:

- Male

- 35 – 65 years old

- Have a Private Pilot License

- Have 500 – 1500 Hrs. TT

- Professional, entrepreneur, or recently retired.

- Pay taxes on $55,000 or more annually

If you don’t meet the above customer profile, don’t despair: You’re probably more than capable of building your own kit aircraft.

Our existing customers tell us that they’ve chosen to build one of our kits for one or more of the following reasons:

- Your company’s been around for more than 20, longer than anyone else – you must be doing something right. I know you’ll be around to provide technical support when I need it.

- The aircraft is professionally designed and has proven itself over the past ten years.

- I want to have the aircraft finished and flying before I die or lose my medical.

- Wow… the flight in your demonstrator was fantastic…performance, comfort and visibility were great… super handling characteristics… offers everything I want in my aircraft!

- I’ve been following Chris Heintz’ designs for a long time now, and his reputation in the business is unparalleled.

- My friend who’s building one said I shouldn’t even bother looking at other designs….

- It offers the best value and features for the least money.

- This is a project that I know I will actually be able to finish and fly.

- The plane’s all-metal so I can store it outdoors, and I can operate it from my grass strip.

- Factory support is very important, and your company is dedicated to helping builders complete their projects.

- The handling characteristics make it safe for me to fly with my limited experience.

- For the money and time I’m investing in this project, I want an aircraft that will last a long time and that will still have a resale value in ten or twenty years.

- You people actually spent time with me showing your aircraft and answering all my questions instead of pushing to close a sale.

All of our kit aircraft are similar in both construction and price. However, they are quite different once completed and flying. You need to decide exactly what features you want in an aircraft and what type of flying you’ll be doing the majority of the time. Be realistic in setting your expectations and requirements.

We don’t think that one of our designs is the “best.” Each design was developed specifically to meet certain requirements. Choose the design that best meets your requirements.

Related Resource:

Chris Heintz Design College

Choosing the Kit Aircraft That’s Right for You

Resale value of kit (experimental) aircraft varies on a number of different factors. It is thus difficult, if not impossible, to forecast resale value for a particular kit aircraft.

A number of factors strongly influence resale value of a kit aircraft:

- Reputation And Popularity Of Design

- Operation / Service History

- Aircraft Type: Utility, Ease Of Flying, Gear Configuration, etc.

- Workmanship And Aircraft Finish By Builder

- Operating Costs & Maintenance Requirements

- Market Conditions: Number Of Aircraft On The Market, Resale History…

Historically, Zenair designs have maintained excellent resale values. This can be attributed to:

- Excellent Reputation / Service History Of Aircraft

- Durability – All-Metal Construction (used aircraft are often in ‘like-new’ condition)

- Ease Of Inspection – Metal Construction Can Easily Be Inspected By Any Mechanic For Structural Integrity / Workmanship (vs. composites)

- Low Operating Costs / Efficiency

- Ease Of Flying / Good Characteristics / Capabilities (suitable for the majority of the pilot population vs. specialized aircraft)

- Market Demand – Very Few Used Ones Available (owners tend to keep them)

- Availability of Manufacturer / Designer Support and Spare Parts

- High Level Of Owner Satisfaction.

FAR 21.191(g) states that eligible amateur-built kit aircraft are “fabricated and assembled by persons who undertook the construction project solely for their own education or recreation.” As such, a kit aircraft must not be built for the purpose of reselling the assembled aircraft, but for the owner’s and builder’s own education or recreation.

As explained above, a kit aircraft is officially defined by the FAA as an aircraft built by an individual “solely for their own education and recreation”. Therefore, if you don’t plan on building yourself, or if you don’t have the time or interest to build, consider buying a completed (used or new) aircraft instead.

If you enjoy flying, but have no interest or mechanical inclination with how an aircraft works, it’s best you leave the building and maintenance to persons who are interested and capable. For most builders, building and maintaining an aircraft is a hobby, and as such, it should be an activity that is enjoyed – you’ll probably be good at it if you enjoy it, and you’ll enjoy it if it is something that you want to do.

Many of our customers have stated that their kit aircraft construction project has been one of the most rewarding (and sometimes challenging) projects that they have undertaken and accomplished in their lifetime.

When purchasing an aircraft kit, remember that you’re not buying a completed aircraft but that you’re obtaining the means to complete an aircraft.

The Experimental Aircraft Association is an excellent resource and valuable service available to existing and potential kit builders. Join EAA and also join a local EAA Chapter to meet with other builders and be part of the exciting world of sport aviation. EAA publishes a high quality monthly publication and sponsors fly-in conventions including the annual Oshkosh fly-in. Other programs / member benefits include the Technical Advisor Program, Flight Advisor Program, Aircraft Finance Plan, Aircraft Insurance Plan, and more. To join EAA, call 1-800-322-2412. (Many other very good sport aviation organizations also exist outside the United States).