By Chris Heintz

[One of the most common questions asked of the Zodiac is about the design’s lack of a piano hinge on the ailerons. The near full-span ailerons use the top aileron skins as the “hinge” to provide aileron deflection. Following, Chris Heintz briefly discusses the reasoning behind the Zodiac’s aileron design].

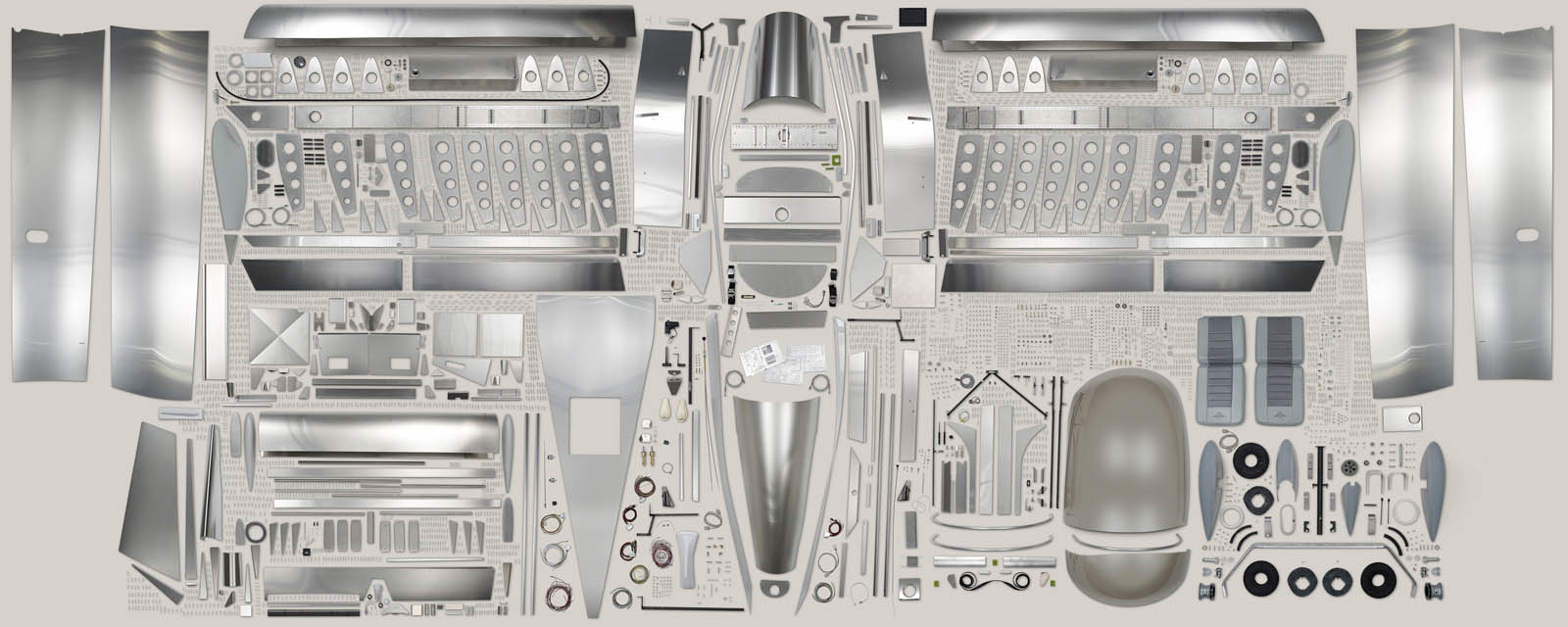

Wing Side View Schematic

Regarding the “hingeless ailerons” on the ZODIAC CH 601 series:

Whereas a hinge has rotating parts (friction, wear and the need to be lubricated), the “hingeless hinge” has no parts with relative motion because the deflection is provided by flexing part ‘a’ (which is an extension of the aileron skin). If the length ‘a’ is of the order of 3/4″ to 1″, the thickness of the flexing metal being .016″, the metal being 6061-T6, and the deflection of the aileron a maximum of +/- 15 degrees, we can, using available deflection statistics for recreational airplanes, calculate the fatigue life of the metal.

Aileron: Side View Schematic

It is some 120,000 hours, which, reduced by the safety factor of 8 (usual when analysis is performed), amounts to 15,000 hours flying time.

Now to be absolutely sure, we also performed fatigue tests. It was easy to replace the aileron bellcrank with an electric motor and an eccentric moving the rod and aileron. We had 3 eccentrics for 3 stages of deflection to reproduce the above mentioned statistics and, knowing that the motor’s RPM is 1700, we get 100,000 cycles per hour (CPM).

Aileron Assembly – Side View Schematic

In a relatively short period, the cycles from the statistics could be applied to the deflection of the aileron for an aircraft utilization of 10,000 flying hours. No crack (not even chipped paint) was noticed.

After that, and just to know if by any bad luck it did crack, do I have to repair it in the field, or can I fly safely home and fix it in the shop? I cut a 1/8″ notch at both inboard and outboard ends of the flex area with snips and restarted running the tests.

After the equivalent of another 3 hours, the notch had developed into a crack reaching on one end the first rivet, and on the other end the second rivet through the wing skin and rear channel. The test was then continued for the equivalent of another 10,000 flying hours with no further deterioration.

The conclusions are: The “flex hinge” is adequate for the intended use (10,000 flying hours, which is an awful lot of time considering that most of us fly about 50 hours per year; it’s 200 years!). Also, if a (very unlikely) crack would be discovered at the preflight check, you can safely fly home and then repair it! I know of at least two Zodiacs having logged over 1600 and 2100 hrs. respectively without any problem, so it definitely works!

A conventional hinged aileron adds weight and does not “look as good” as the maintenance-free hingeless aileron – with its smooth surface and completely sealed gap.